Welded wire fences are broadly recognized as an adaptable fencing method for myriad applications such as residential and agricultural areas. They come with a mighty configuration, customizable options, and a multitude of other benefits. However, it doesn’t mean they’re free from any limitations.

In our post today, we tend to discuss all the benefits and drawbacks of welded wire fences. We’ll also talk about their applications, how to install them, and more. Read on to find out everything you need to know about this prevalent style of fence.

Table of Contents

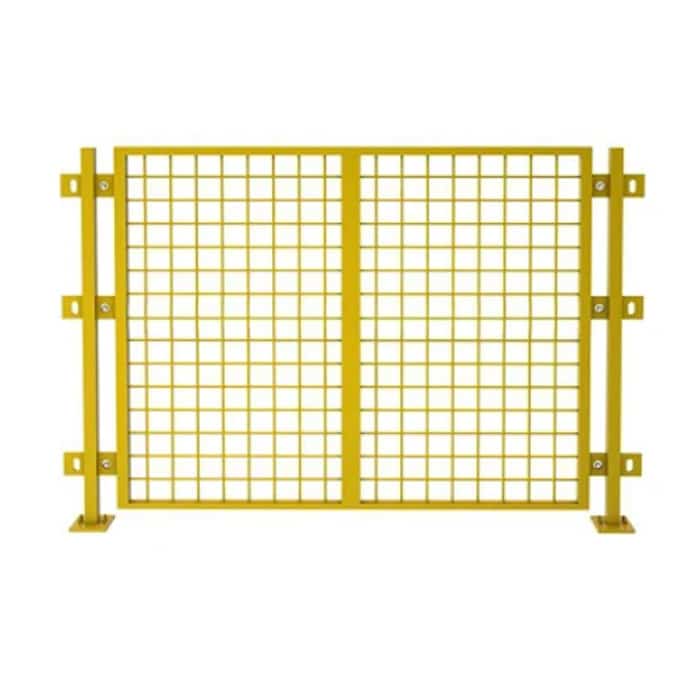

What is a Welded Wire Fence?

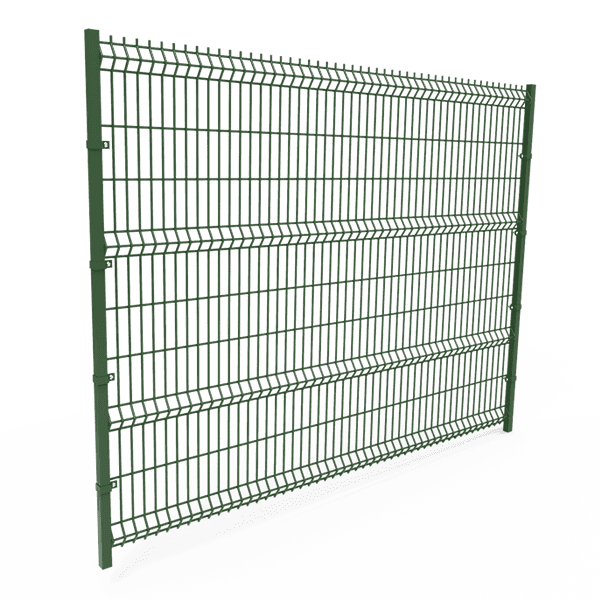

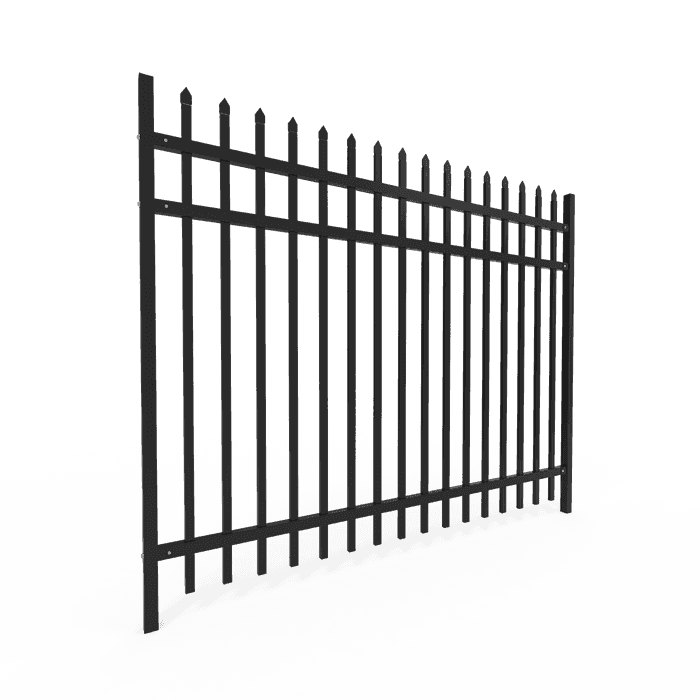

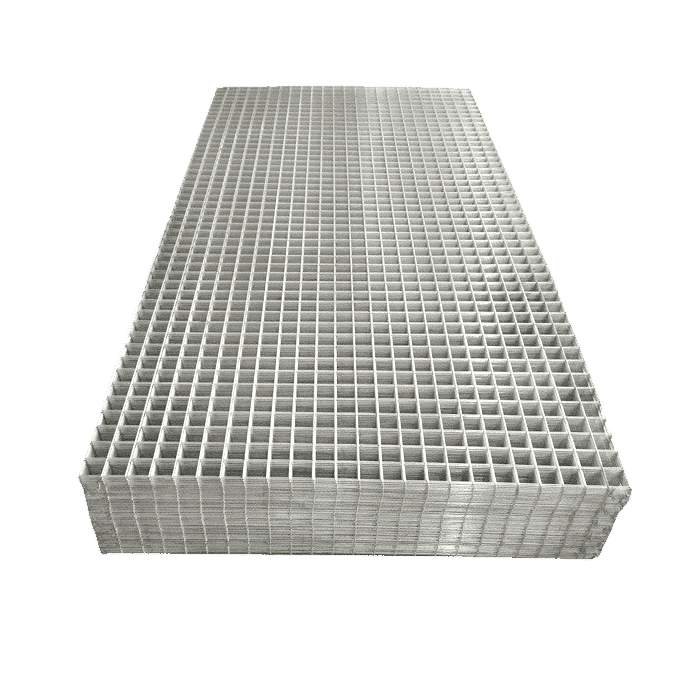

A welded wire fence is a type of fence that’s made from horizontal and vertical wires. These wires are welded jointly at each junction to produce a grid pattern. This grid pattern is a formidable barrier for myriad applications such as in residential, commercial, agricultural, and industrial regions.

The wires of a welded wire fence are usually constructed from steel, which is vigorous and resists bending or breaking under pressure. Such fences come in diverse heights, mesh sizes, and wire gauges fitting for an expansive mixture of preferences.

Furthermore, you can personalize welded wire fences with distinct coatings or finishes such as galvanization or vinyl coating. This fortifies the fence’s resistance to corrosion and makes it practical for outdoor usage in diverse weather conditions.

It’s rather simple to install welded wire fences because you can easily use fasteners or ties to connect panels to posts or current structures. The simplicity of installation makes this type of fence a wonderful choice for both DIY lovers and dexterous installers.

Welded wire fences are generally a budget-friendly and functional option to secure a property, contain livestock, outline boundaries, and deliver safety and privacy. Let’s discuss their advantages in detail below.

The Advantages of a Welded Wire Fence

Welded wire fences come with a bunch of benefits in diverse applications because of their durability, versatility, and simple installation. Here are some of their critical advantages:

1. Strength and Durability

As we discussed, horizontal and vertical wires are welded together at their intersections to form a welded wire fence. This leads to heightened rigidity and strength of the fence’s grid pattern.

Such a unique design delivers outstanding structural harmony. This way, welded wire fences become resistant to bending, sagging, or breaking. They can survive well under harsh weather conditions, impacts from debris, and the pressure resulting from leaning/climbing animals.

2. Versatility

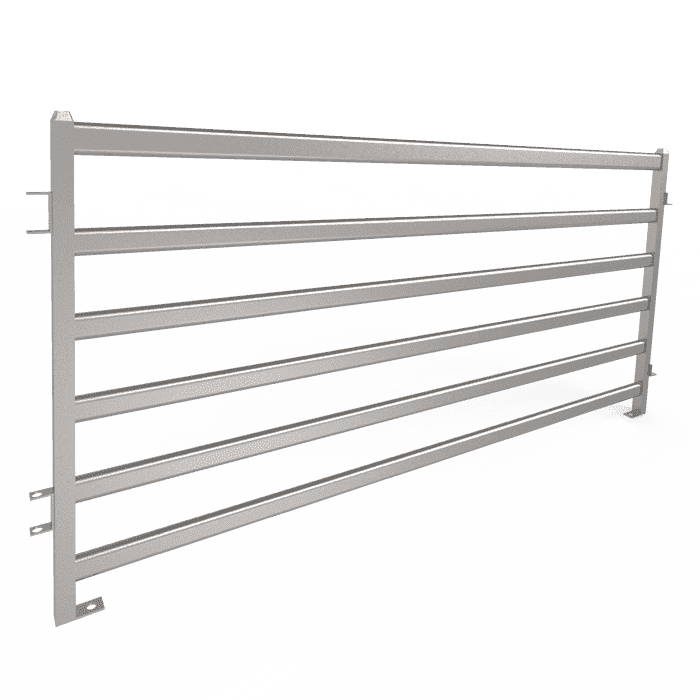

Welded wire fences are designed in myriad heights, mesh sizes, and wire gauges for various desires. There’s always a proper welded wire fence for any application, including a small garden enclosure, a large livestock pasture, or a commercial property perimeter.

What’s more, these fences can be effortlessly cut to your preferred size or trimmed to fit uncommon shapes. This maximizes their personalization options so they can fit your specific demands.

3. Customization Options

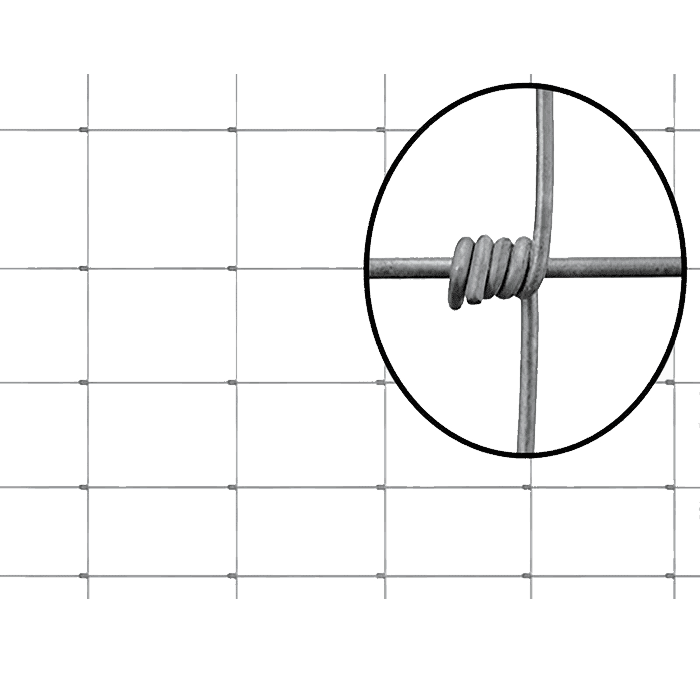

Welded wire fences can be personalized with diverse coatings/finishes to sweeten their performance and prolong their lifespan. They’re commonly galvanized where wires are coated with a zinc layer to heighten their corrosion resistance, especially in outdoor atmospheres.

Besides, you can coat these fences with vinyl or PVC to elevate their protection against rust, scratches, and UV damage. This also sweetens their appearance with different colors and textures.

4. Effortless Installation

It’s rather straightforward and simple to install a welded wire fence. Both DIY fans and expert installers can do the job with elementary tools. The fence panels are usually lightweight and mobile, thereby being easily transportable into the position.

These panels can be effortlessly connected to wooden, metal, or concrete posts using fasteners, clips, or ties. They can be easily modified during the installation to confirm appropriate alignment and tension.

5. Negligible Maintenance

Compared to other types of fences, welded wire fences demand negligible maintenance tasks. The mighty building and shielding coatings of these fences thwart rust/corrosion and diminish the need for frequent painting or treatment. Maintenance tasks usually comprise sporadic cleaning to remove dirt and debris and scanning for indications of wear and damage.

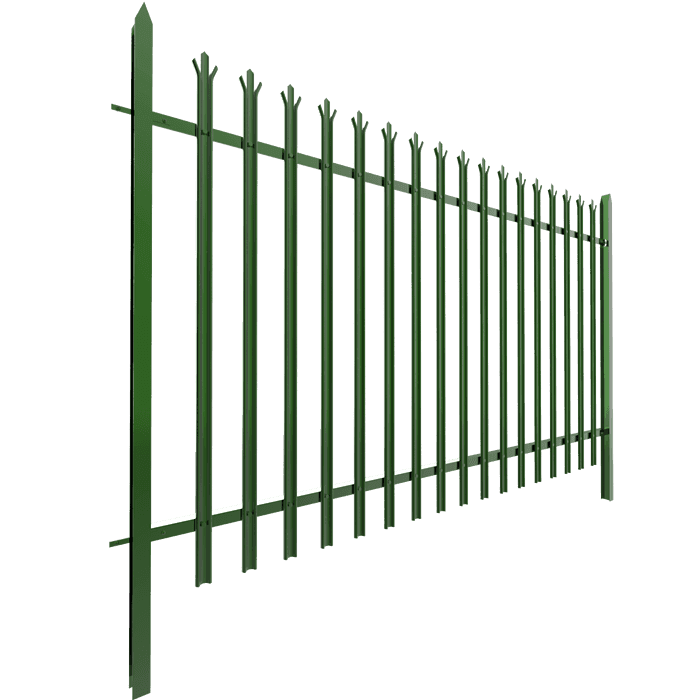

6. Security and Protection

Welded wire fences provide properties, assets, and occupants with the required security and protection. Their strong configuration and impenetrable mesh pattern create a tough barrier that hinders trespassers, intruders, and wildlife from unauthorized entrance. Plus, when installing, these fences can be merged with extra security components such as barbed wire, razor wire, or electric fencing systems for elevated defensive capabilities.

7. Cost-Effectiveness

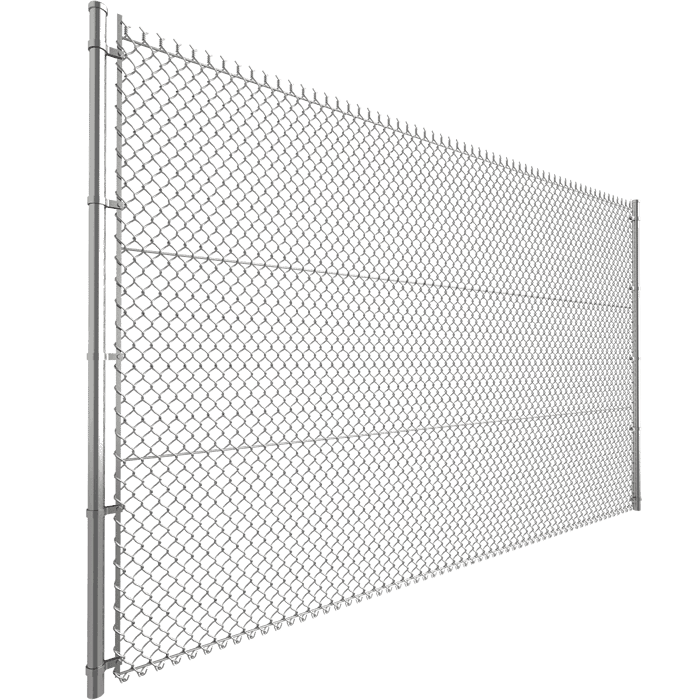

Welded wire fences are usually more budget-friendly in comparison with other fence materials such as wood, chain link, or wrought iron. This is particularly more perceptible when you consider the strength and endurance of these fences.

Although the primary investment in materials and installation of these fences is somewhat higher, it’s compensated by their lowered maintenance and replacement costs. This still places these fences among the most cost-effective fencing options out there for anyone.

The Disadvantages of a Welded Wire Fence

Despite all the advantages of welded wire fences, they have some weaknesses too.

1. Restricted Flexibility

These fences aren’t as adjustable as other types of fences, such as chain links or mesh fences. They have a hard-and-fast grid pattern that makes them difficult to fit uneven terrain or curved edges without modification.

2. Prone to Rust and Corrosion

Although these fences are furnished with protective coatings like galvanization or vinyl, they still encounter rust/corrosion in the long run. This is exacerbated in damp areas or where corrosive elements such as salt or chemicals are present. Routine maintenance — including cleaning and periodic recoating — might be necessary.

3. Potential for Damage

Welded wire fences can be damaged due to impacts, bending, or cutting. Excessive force can break welded connections and weaken the fence’s integrity. Plus, sharp edges and protruding wires might be hazardous for pets, kids, and others in crowded areas.

4. Higher Initial Cost

In comparison with other fences like chain links or wooden fences, welded wire fences can come with a higher initial cost, though it depends on your certain requirements and customization options. You will eventually enjoy cost savings due to diminished maintenance, but the upfront investment might be discouraging for some buyers.

5. Challenging Repairs

Repairing this type of fence is somewhat tougher than others. You may need special tools to repair a damaged segment, such as a broken wire or a bent panel. Also, it might be tough to match the appearance of the repaired section with the rest of the fence. Thus, repairing these fences can force you to ask for help from experts, which is pricey and time-consuming.

The Applications of Welded Wire Fences

Welded wire fences come with a multitude of applications in diverse sectors. Some more known applications of these fences are:

- Residential Fencing: These fences are largely employed in residential neighborhoods to pinpoint property borders, improve security, and shield kids and pets. They can be erected around backyard gardens, pool areas, or entire properties. This is to prevent disallowed entrance, discourage trespassers, and at the same time, conserve the beauty and visibility of the surroundings.

- Agricultural and Livestock Enclosures: In these areas, welded wire fences create an enclosure for livestock such as cattle, horses, sheep, and poultry. These fences function as a barricade to contain animals and prevent them from wandering onto neighboring properties. They also shield crops from grazing and create smaller enclosures for gardens, orchards, or apiaries to protect plants and beehives from wildlife.

- Commercial and Industrial Security: In these areas, welded wire fences can secure premises, guard invaluable assets, and manage entrance. They’re widely employed around warehouses, factories, construction sites, and storage yards to prevent theft, vandalism, and unauthorized entrance. Their optional safety features such as barbed wire, razor wire, or electric fencing systems heighten their defensive strength against intruders.

- Infrastructure and Utilities: Government agencies, utilities, and transportation authorities employ these fences to protect integral infrastructure such as roads, railways, bridges, and electrical substations. Welded wire fences prevent unauthorized entrance, vandalism, and sabotage, and at the same time, safeguard infrastructure assets.

- Recreational Facilities: Welded wire fences are pitched in recreational areas such as parks, playgrounds, sports fields, and community centers. This is to determine boundaries, guarantee visitor safety, and protect establishments. They’re widely used to encircle play zones, ball fields, and swimming pools. They can also create partitions for seating locations or equipment storage.

How to Install a Welded Wire Fence?

To install a welded wire fence, you can follow these steps in a row:

Step 1 – Plan and Measure

Determine the layout of your fence. Mark the boundaries with stakes and string. Measure the length of each fence run. Calculate the quantity of materials you need, including fence panels, posts, fasteners, and gates.

Step 2 – Prepare the Site

Remove any vegetation, debris, or obstructive objects from the fence line. Make sure the ground is level and free from rocks/roots that may limit the placement of posts.

Step 3 – Install Corner and End Posts

Start with installing corner and end posts. Employ a post hole digger to dig holes spaced at least one-third of the post length. Make sure they’re deep enough to remain unmoving. Insert the posts into the holes and see if they’re plumb and level. Then, backfill with concrete/gravel before you let it cure based on the manufacturer’s instructions.

Step 4 – Set Line Posts

Space line posts evenly along the fence line — typically 6 to 8 feet apart — depending on the fence height and terrain. Dig post holes using a post hole digger and set the posts in place. Make sure they’re aligned and level. Then, backfill the holes with concrete/gravel and let them cure.

Step 5 – Attach Fence Panels

Then, connect fence panels to the posts employing fasteners/ties. Start at one end of the fence line and keep going forward. Make sure panels are aligned and affixed well to the posts. Use a level to see if the panels are straight and plumb.

Step 6 – Install Gates

If your fence is equipped with gates, install them as per the manufacturer’s guidelines. Make sure they’re connected tightly to the posts and operate smoothly.

Step 7 – Finishing Touches

Trim any extra wire from the panels. Scrutinize to find loose or protruding wires. Make adjustments/repairs if necessary until the fence is secure.

How to Stretch a Welded Wire Fence

It’s integral to properly stretch a welded wire fence as it causes the fence to remain tough and secure between posts. To do so, anchor the end of the fence to a strong object using fence stretcher bars or come-alongs. Use chains/straps to connect the stretcher bars to the end of the panel and secure them to the anchor point.

Then, connect tensioning tools — such as fence stretcher bars or come-alongs — to the opposite end of the panel. These tools apply tension to the fence and tighten it between the posts.

It’s now time to slowly crank or ratchet the tensioning tools to apply tension to the fence. Gradually tighten it between the anchor point and the opposite end. Don’t tighten it too much as it may damage the fence. Throughout the stretching process, occasionally assess the alignment and tension of the fence. See if it’s straight and fixed between posts, and make adjustments if necessary.

Once the fence is stretched to your preferred tension, fasten the ends to the end posts securely using fence staples, ties, or fasteners. These steps help you appropriately stretch the fence and confirm its toughness. Still, routine maintenance and inspection of the fence shouldn’t be forgotten.

Final Words

Today, welded wire fences are widely recognized as a practical fencing method that’s employed in diverse applications. They deliver myriad benefits such as durability, simple installation, cost-effectiveness, customizability, and more.

Although they come with a few drawbacks such as the potential for damage and more challenging repairs, their advantages surely outweigh these drawbacks in numerous scenarios.

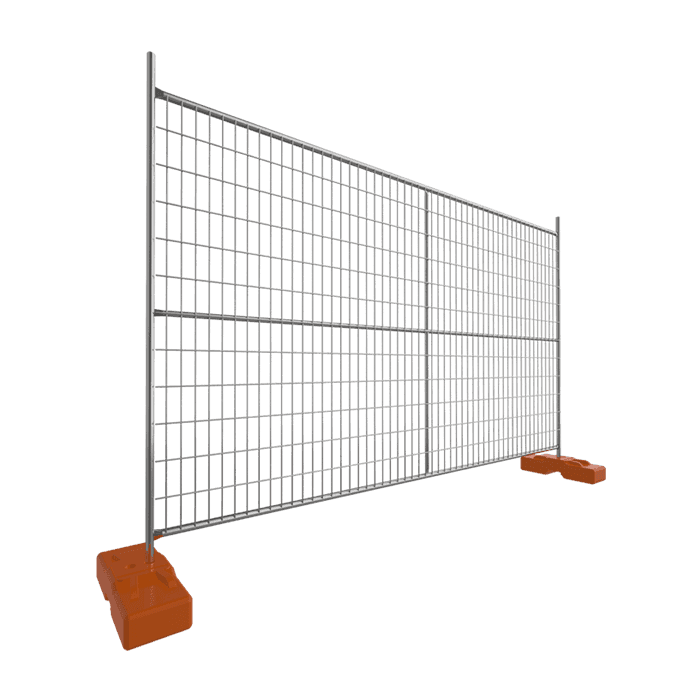

Related Post might be HELPFUL to you: 5 Steps to Build a Temporary Fence with Ease